In the realm of apparel printing, technology has dramatically diversified the choices available to brands and businesses. The age-old method of screen printing now stands alongside digital techniques such as Direct-to-Garment (DTG) and Direct-to-Film (DTF) printing. But with more choices comes more decision-making. Which method is right for you?

Before we delve into the specifics, let’s take a moment to recap what these three printing methods are:

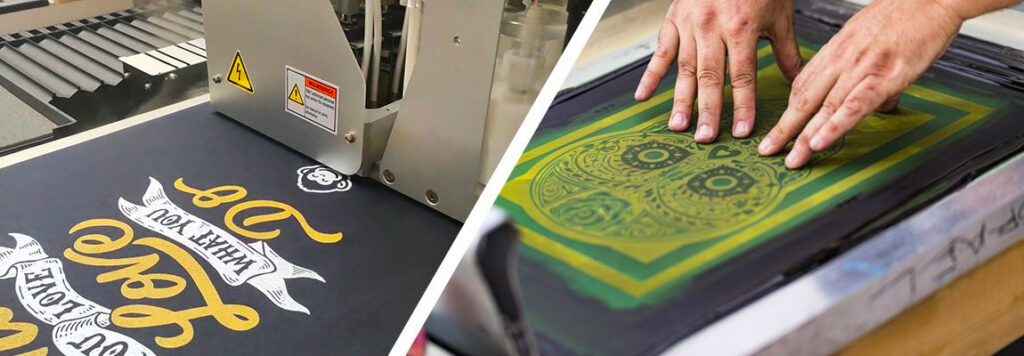

Direct-to-Garment Printing: Often hailed as a revolution in the apparel industry, DTG printing leverages the principles of standard inkjet printing, but extends it to textiles. Utilizing a range of aqueous textile inks, specialized printers spray the ink directly onto the garment, replicating the desired design with precision. The colors are vibrant, the details are sharp, and the ability to render complex graphics is unparalleled. This technique doesn’t require any setup for specific designs, making it perfect for one-off prints and small batch orders.

Direct-to-Film Printing: The DTF printing process is a technological advancement in the digital printing realm. It employs inkjet printers to deposit ink onto heat transfer films. These films, bearing the reversed print of the design, are then heat-pressed onto the garments, transferring the design onto the fabric. With its ability to support multi-colored designs and its suitability for a broad range of fabrics, DTF brings a versatile edge to your printing projects.

Screen Printing: An ancient art form, continues to be a stalwart in the printing industry. This method involves creating a stencil, or a “screen,” for each layer of color and then using it to apply ink onto the fabric. While it may not excel in reproducing intricate designs or color gradients, its strength lies in producing durable, vibrant, and cost-effective prints, especially for bulk orders.

Designing For Each Print Method

When it comes to creating your graphic designs for each method, understanding the capabilities and limitations of each process is crucial.

Designing for Direct-to-Garment Printing: When designing for DTG, you can think of your garment as the canvas and the design software as your palette. You’ll primarily be using software such as Adobe Photoshop or Illustrator. Photoshop, which deals with raster images (made up of pixels), is perfect for photograph-based or complex multi-colored designs. On the other hand, Illustrator, which deals with vector images (composed of mathematical equations to render graphics), is excellent for designs requiring scalability without losing quality. DTG does not require color separations, so you can create designs with unlimited colors, gradients, and detailed elements. However, it’s crucial to consider the garment color. On darker garments, a white ink underbase may be required for colors to show up vividly. Always ensure your design’s resolution is high (300 DPI is recommended), and the design size matches the print area on the garment.

Designing for Direct-to-Film Printing: Designing for DTF is quite similar to DTG, with the primary difference being that designs must be mirrored before printing. This is because the design is printed onto a film before being heat-transferred onto the fabric. Whether you’re using Photoshop for a pixel-perfect graphic or Illustrator for a crisp, scalable design, always remember to flip your design horizontally before saving. Like DTG, DTF allows for full-color designs, but always consider the type of fabric your design will be printed on as results can vary across different materials.

Designing for Screen Printing: Designing for screen printing is a bit different and can be more complex due to color limitations and the need for color separations. For multicolor designs, each color must be isolated and printed onto its own film to create screens for printing. Software such as Adobe Illustrator is typically used for this process due to its powerful color separation features. For instance, if you have a logo design in Illustrator that uses four colors, you’ll need to create four separate layers – one for each color. Each layer will then be printed onto a separate film positive, which will be used to create the screens for printing. With screen printing, fewer colors generally mean a more cost-effective project. If your design requires a lot of colors, consider using halftones (a pattern of small dots that can simulate different shades of color) to reduce the number of screens needed. Screen printing excels at bold, vibrant designs with solid colors, so keep that in mind when creating your artwork.

Choosing the Best Printing Method for Your Needs

Now that we’ve delved into the ins and outs of each printing method, it’s time to evaluate how they stack against one another based on individual project needs. There is no one-size-fits-all solution; the best printing method depends on a variety of factors.

DTG Printing: If you’re dealing with highly intricate designs or photographs that need accurate color reproduction, or if you have a requirement for low-volume, customized, or on-demand orders, DTG is a formidable contender. Its ability to recreate nuanced details with no color limitation is its biggest strength. However, it’s essential to bear in mind that the per-unit cost with DTG can be higher than other methods, especially for large orders.

DTF Printing: For those who require versatility, DTF shines brightly. From cotton and polyester to leather and canvas, DTF can handle a wide variety of fabrics. It’s also a strong contender for projects involving complex, multicolor designs and small batch orders. However, the process involves plastic films that may not align with sustainability-focused brands.

Screen Printing: For large orders that require durability and a vibrant finish, traditional screen printing steps in as the most economical choice. Although the initial setup can be time-consuming, the cost per unit drops significantly for high-volume orders, making it cost-effective. Moreover, screen printing’s color brightness and durability are hard to beat, especially for solid color designs. However, it’s not the best fit for designs requiring detailed color gradients or low-volume orders.

In conclusion, selecting the right printing method for your apparel is not just about cost, quantity, or convenience—it’s about making your vision come to life in the most vibrant, durable, and high-quality way possible. Whether it’s the crisp detail of DTG, the versatile adaptability of DTF, or the bold vivacity of screen printing, each method offers a unique path to actualize your design aspirations. But making the right choice can feel daunting, and that’s where we step in. With our expertise in all three methods, we’re not just printers—we’re your printing partners, committed to navigating you through this journey, making your decision-making process smooth and rewarding. Our dedication to delivering superior quality, personalized solutions, and excellent customer service sets us apart. But don’t just take our word for it. Let us show you what the perfect print looks like—tailored to your needs, respectful of your budget, and beyond your expectations. Reach out to us today for a no-obligation chat about your printing needs. Because at the heart of it all, your vision deserves to be worn and celebrated. We’re here to make that happen.