If you’re looking to start a clothing brand or need to create custom apparel for your business, you are probably wondering whether you should use a direct-to-garment (DTG), direct-to-film (DTF), or screen printing method. These printing methods have their own advantages and disadvantages, and which one is right for you will depend on your specific apparel needs and preferences. In this article, we’ll take a closer look at the differences between DTG, DTF, and screen printing to help you make an informed decision on which process to choose to print your clothing.

What is DTF printing?

DTF, or direct-to-film printing, is a digital printing method that uses specialized inkjet printers to apply ink onto heat transfer sheets that are then applied to individual garments. Direct-to-film printing is ideal for creating high quality prints with lots of detail and color, and is typically used to print samples or small quantities of shirts (Less than 100).

Advantages of DTF Printing

One of the biggest advantages of DTF printing is its versatility. DTF transfers can be applied to a wide variety of fabrics including cotton, polyester, and blends. This means that you can create custom apparel for a wide range of applications across streetwear, casual, and performance apparel using the direct-to-film process.

DTF printing is also ideal for printing complex designs with many colors. Because the ink is applied digially, there are no limitation to the number of colors that can be used in the design. For this reason, DTF printing is also ideal for printing photographs or other high resolution images.

Disadvantages of direct-to-film printing

- Lower print quality on certain materials: While DTF printing is versatile in terms of the range of fabrics it can be used on, it may not produce the same quality prints on certain materials as other printing methods. For instance, it may not be suitable for printing on nylon or other synthetic fabrics.

- Higher upfront costs: DTF printing requires specialized equipment, such as inkjet printers, heat transfer sheets, and pre-treatment sprays, which can be costly to purchase and maintain. This makes it a less cost-effective option for small-scale printing projects.

- Time-consuming process: DTF printing requires multiple steps, including pre-treatment of the garment, printing, and heat pressing. This can be a time-consuming process, especially when compared to other printing methods such as DTG printing, which can print directly onto garments without the need for transfer sheets.

- Limited durability: DTF prints may not be as durable as other printing methods, such as screen printing or embroidery. The prints may fade or crack over time, especially when exposed to frequent washing or heavy use.

- Environmental concerns: The DTF printing process involves the use of various chemicals, such as pre-treatment sprays and ink, which can be harmful to the environment if not disposed of properly. Additionally, the transfer sheets used in DTF printing cannot be recycled, which can lead to additional waste.

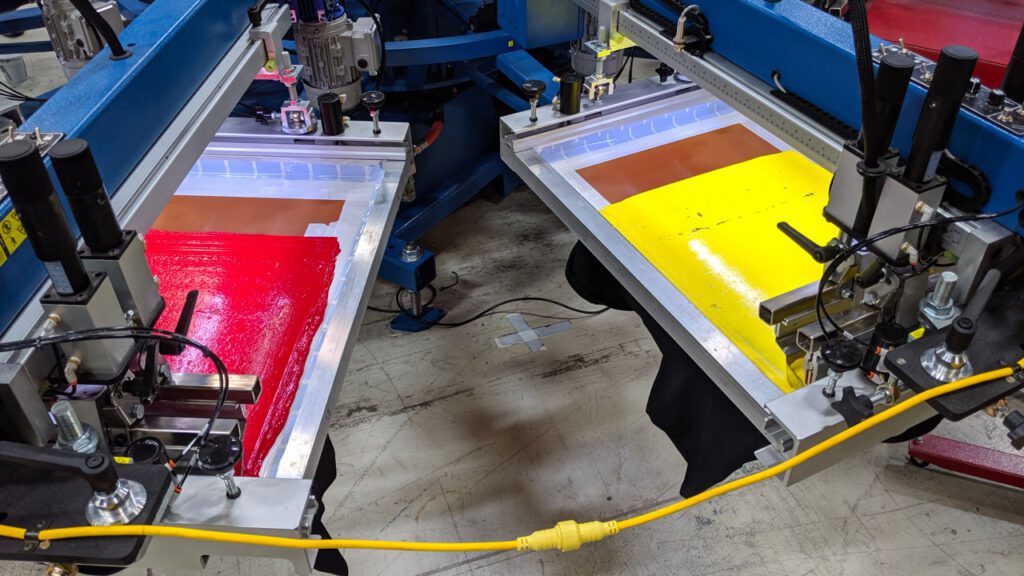

What is Screen Printing?

Screen printing, also known as silk screen printing, is a traditional printing method that has been used for centuries. Screen printing involves creating a stencil or “screen” and then using it to apply ink onto the fabric. Screen printing is ideal for creating high-quality, long lasting prints with vibrant colors.

Advantages of Screen Printing

One of the most significant advantages of screen printing is its durability. Screen prints are known for their longevity and can withstand multiple washes and wears without fading or cracking. This is due to the thick layer of ink that is applied to the fabric, which creates a vibrant and long-lasting image. As a result, screen printing is an excellent choice for printing designs on items such as t-shirts, tote bags, and other clothing items that will be worn frequently.

Another advantage of screen printing is its cost-effectiveness. While the setup costs for screen printing can be high, the cost per print decreases as the quantity increases. This makes screen printing ideal for large quantities or for printing on a regular basis. For example, if you need to print a large number of t-shirts for an event or a promotional campaign, screen printing is likely the most cost-effective option.

Screen printing also offers a lot of versatility in terms of the types of fabric it can be used on. It can be used on a wide range of materials, including cotton, polyester, nylon, and more. This makes it a popular choice for printing on a variety of items, including clothing, bags, and other promotional products.

Disadvantages of Screen Printing

One of the biggest disadvantages of screen printing is the limitations on color. Each color in the design requires a separate screen and most machines are limited to how many screens can fit on the heads at one time. Most shops also charge for each screen used, which will make setup costs more expensive the more colors you use.

Lastly, screen printing is very cost effective when doing large quantities, however, smaller orders will likely be more expensive due to the labor and time that goes into preparing the screens. For this reason, screen printing is not ideal for small quantities or on-demand prints.

What is DTG printing?

Direct-to-garment (DTG) printing is a modern digital printing method that involves using specialized inkjet printers to apply ink directly onto garments, much like a traditional inkjet printer would print on paper. DTG printing is ideal for creating high-quality prints with lots of detail and color, making it a popular choice for custom apparel, small-scale printing projects, and on-demand printing.

Advantages of DTG Printing

One of the most significant advantages of DTG printing is its ability to produce high-quality prints with incredible detail and vibrant colors. The digital process allows for high-resolution prints with a wide range of colors, gradients, and shading, making it ideal for printing photographs, intricate designs, or artwork. The process also ensures consistency in color and quality across all prints, regardless of the garment or order quantity.

DTG printing is also a versatile printing method that can be used on a wide range of materials, including cotton, polyester, and blends. Unlike some other printing methods, DTG printing does not require any additional steps, such as transfer sheets or screens, which makes it a quick and efficient printing method. This makes it an ideal choice for small-scale printing projects, on-demand printing, and custom apparel orders.

Disadvantages of DTG Printing

While DTG printing offers many advantages, there are some disadvantages to consider as well. One of the most significant disadvantages is that the ink used in DTG printing is not as opaque as other printing methods, such as screen printing. This means that the ink can be absorbed into the fabric, which may result in a less vibrant and crisp print, especially on darker colored fabrics.

Another disadvantage of DTG printing is its limited durability. The prints may fade or crack over time, especially when exposed to frequent washing or heavy use. This makes it less suitable for printing on items that will be subjected to frequent washing or heavy use, such as sportswear or workwear.

DTG printing can also be more expensive than other printing methods, especially for larger orders. While the process is quick and efficient, the cost of the specialized equipment and ink can be significant, which makes it less cost-effective for larger orders.

Which Printing Method Should You Choose?

When deciding on a printing method for your apparel needs, it is essential to consider your specific requirements, including budget, order quantity, garment type, and design complexity. DTG printing is ideal for small-scale printing projects, on-demand printing, or custom apparel orders, especially when intricate designs or high-resolution images are involved. Screen printing, on the other hand, is a cost-effective option for larger quantities and offers more durability, especially for items that will be subjected to frequent washing or heavy use.

In conclusion, each printing method has its own advantages and disadvantages, and it is crucial to evaluate your specific needs and preferences to choose the best printing method for your apparel needs. Whether you choose DTG, DTF, or screen printing, the key is to select a printing method that can provide the desired quality, durability, and cost-effectiveness for your specific apparel needs.