Your performance venue is gearing up for a new season and now is the time to make sure all of your staff look their best. Just as your venue sees many different kinds of musicians, plays, musicals, and more, there are many different ways to outfit your various work crews. From front of the house to ushers, security to custodial staff, they all need uniforms, and you have to pick the right printing for the job.

Vinyl printing is probably the most straightforward of all printing methods, but it is also the one with the least room for creativity. It is ideal for single color lettering and designs, and creates logos that can stand the test of time. But before we jump into what mkes vinyl printing a great method, let’s first get a bit more detail about how the vinyl printing process works.

The How’s & Why’s Of Vinyl Printing

Very simply, vinyl printing involves using heat and pressure to apply cut vinyl to garments. Commercial printers mostly use CAD-cut vinyl, or Computer-Assisted Design, both for speed and precision. Computer-assisted design ensures that all letters and numbers meet the standards for every different job and removes human error from the equation entirely. CAD-cut vinyl:

- Has a durable finish that is washable and sturdy, and that never peels, cracks, or fades.

- Is easy to apply.

- Comes in lots of colors and styles, including matte and glossy finishes, glitter, fluorescent or metallic, patterns, holographic effects, and patterns.

- Is easily adaptable for modification and repair.

- Has no setup time, which makes it efficient.

- Can be used on any colors, and is ideal for dark colors. Unlike screen printing and direct-to-garment printing, which allow darker colors to show through light inks, vinyl appliqués are solid. This means you can use light-colored vinyl on dark material and it will show up brilliantly.

- Works well on many different kinds of fabric, including cotton and natural fibers, cotton-poly blends, and synthetics.

Now that we’ve established the positives of vinyl versus other types of printing, let’s take a closer look at the application process.

Vinyl Printing How-To’s

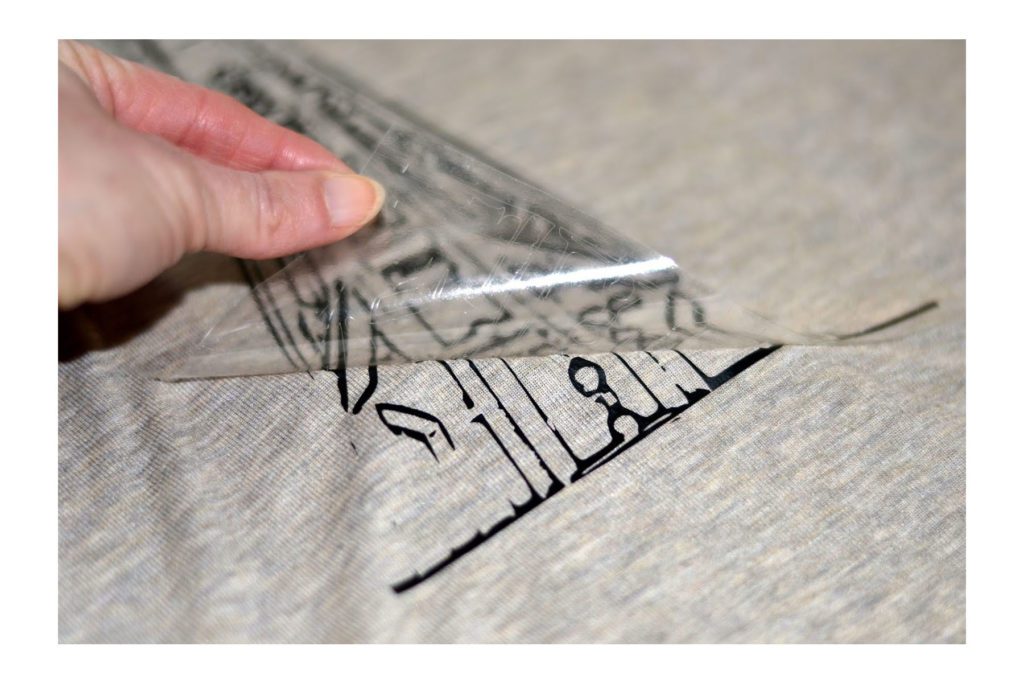

Once your vinyl is cut, you need to “weed” it. This means that you have to remove the extra vinyl, or negative space, so that all that’s left on your transfer sheet is your lettering or design. This can be time-consuming if you have lots of small spaces or intricate designs, which is why vinyl is most frequently used for basic lettering and large designs. Weeding can be done with any sharp pointed tool, and be careful and pay attention, you don’t want to weed your actual design!

Now your transfer film has only your design, and you’re ready to start applying it. You need a combination of heat and pressure to transfer the color from the cut-outs to your garment. Industrial garment printers use large presses that work on timers; simply get the design where you want it, but remember: if you’re ready to press but you’re looking at a mirror image of your design, you don’t have it oriented properly. It will stick to the machine, not your garment!

After making sure your garment and your vinyl are properly oriented, cover your transfer film with silicone or Teflon sheets; these ensure the heat is evenly distributed so the transfer goes smoothly. Every brand of thermal transfer sheet has its own specific time, temperature, and pressure settings that will set the design without burning the garment or vinyl, so the settings are fed to the press and then when everything cools down, peel the transfer sheet away and voilà, your garment is ready!

Vinyl Printing For Your Venue

Vinyl printing is cheap, yes, but is really only suitable for smaller runs of 20 shirts or fewer. There is no setup needed, but weeding your transfer takes time, you have to manually set each item before you press, and you can only press one itemt at a time. Additionally, you’re limited to what you can print: t-shirts are the most popular for vinyl printing, followed by sports jerseys, uniforms, and athletic wear.

We recommend using vinyl printing for your venue if you have a small venue with staff of no more than ten people; if you’re a larger venue with a small custodial, security, bar, or front of the house staff, vinyl printing might be a good option if you don’t mind your different crews wearing different, distinct uniforms. Generally speaking, however, if you need a large number of garments, think about screen printing or embroidery instead.

Should you choose vinyl printing, following these tips can extend the life of your garment, so make sure your employees know:

- Never dry clean a vinyl printed garment!

- Machine-wash in warm (not hot!) water with mild detergent.

- Dry on medium-low heat.

- Never use chlorine bleach.

- Let the design cure for at least 24 hours after printing before washing.

Final Thoughts

Vinyl printing has some distinct advantages over screen and direct-to-garment printing, especially when you want to print letters, numbers, and simple designs, you don’t need multiple colors, or if you want to print on dark-colored garments. If you choose vinyl printing, or want to talk through your specific venu’s needs, please reach out; printing is our job and we love sending customers off happy.